Gas leaks pose a significant threat in both domestic and industrial settings. Undetected, they can lead to explosions, fires, and even fatalities. Thankfully, advancements in Internet of Things (IoT) technology have given rise to innovative solutions for gas leak detection, significantly improving safety measures. But before we dive into these advancements, let’s take a step back and understand the scale of gas consumption globally.

The Global Landscape of Gas Consumption

- The International Gas Union (IGU) releases an annual Global Gas Report, but the 2023 edition focuses more on market trends and uncertainties rather than specific consumption figures.

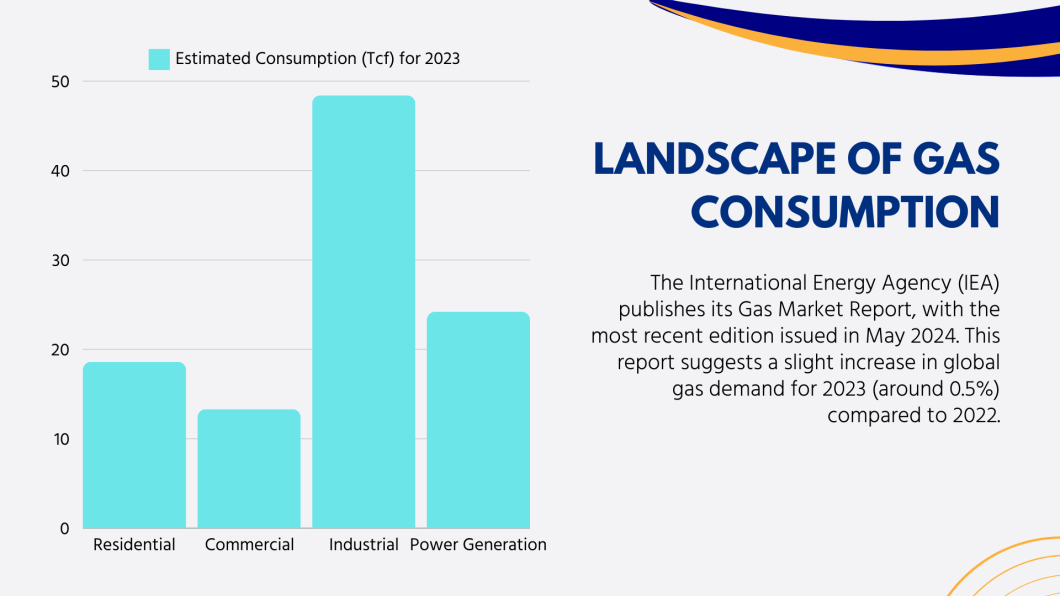

- The International Energy Agency (IEA) publishes its Gas Market Report, with the most recent edition issued in May 2024. This report suggests a slight increase in global gas demand for 2023 (around 0.5%) compared to 2022.

| Sector | Estimated Consumption (Tcf) for 2023 |

| Residential | 18.6 |

| Commercial | 13.3 |

| Industrial | 48.4 |

| Power Generation | 24.2 |

As this table indicates, the industrial sector is the largest consumer of natural gas, followed by power generation, residential use, and commercial use. This highlights the importance of robust leak detection systems across all these sectors to minimize wastage and safety risks.

Table of Contents

The Core of the System: Sensors and Microcontrollers

An IoT-enabled gas leak detection system hinges on two crucial components: sensors and microcontrollers.

The MQ series of metal-oxide-semiconductor (MOS) gas sensors is a popular choice. These sensors are specifically designed to detect various gas types, including natural gas (methane – CH₄) and Liquefied Petroleum Gas (LPG – a mixture of propane – C₃H₈ and butane – C₄H₁₀). The sensor operates on the principle of chemisorption, where gas molecules interact with the sensor’s surface, altering its electrical resistance. This change in resistance serves as the indicator of a potential gas leak.

The collected sensor data is fed into a microcontroller, the brain of the system. A popular choice for this role is the ESP32 microcontroller. This versatile and cost-effective option boasts an integrated Wi-Fi and Bluetooth Low Energy (BLE) module, facilitating seamless communication with the cloud platform. The microcontroller continuously monitors the sensor readings. When the readings exceed a pre-defined threshold, indicating a potential leak, the microcontroller springs into action.

Taking Action: Alerts and Responses

Upon detecting a gas leak, the system can initiate various responses depending on its configuration. Here’s a breakdown of some common actions:

Audible and Visual Alerts: Loud alarms or flashing lights immediately alert occupants to the danger, prompting them to evacuate the area.These are no ordinary beeps. We’re talking about high-pitched, blaring sirens that can’t be ignored.

They ensure everyone in the vicinity is alerted to the danger, prompting them to evacuate the area as quickly as possible. Alongside the piercing alarm, bright, attention-grabbing lights start flashing. This provides a visual cue, especially helpful in situations where the alarm might be muffled or for people with hearing impairments. The combination of sound and light creates a strong sensory warning, leaving no room for doubt about the urgency of the situation.

Remote Notifications: The system can transmit alerts to smartphones or designated contact numbers via SMS or app notifications. This ensures awareness even when occupants are away. A text message is sent to your phone, notifying you of the detected gas leak.

This ensures you’re aware of the situation even when you’re away from home and can take appropriate action, such as contacting emergency services or alerting a neighbor. Some systems can send notifications through a dedicated app on your smartphone for even more convenience. This app might display additional information, such as current gas levels or allow you to monitor the situation remotely.

Automatic Shut-off Valves: In more sophisticated systems, the response goes beyond just alerting occupants. Automatic shut-off valves take a crucial step towards preventing further danger. These valves are essentially like special switches placed within the gas supply line.

When the microcontroller detects a leak, it sends a signal to these valves, causing them to shut off automatically. This effectively cuts off the gas supply at its source, preventing further leakage and significantly reducing the risk of explosions.

Data Transmission to the Cloud: The system doesn’t just react in the moment. It also keeps a record of the event for future reference. This is achieved through data transmission to the cloud. Real-time data on gas levels is sent to a secure online storage platform, often referred to as the cloud. This data can be accessed remotely and provides several benefits:

Even if you’re not physically present, you can check the cloud platform to see current and historical gas level readings. This allows you to assess the situation remotely and make informed decisions.

The cloud data can be analyzed to identify patterns or trends in gas levels. This information can be valuable in preventing future leaks or identifying potential problem areas within your gas system.

Having a record of past gas leak events can be helpful for maintenance purposes or to demonstrate the effectiveness of the gas leak detection system.

Read About: IoT In The Oil And Gas Industry: Use Cases And Challenges

The Advantages of an IoT Approach

Traditional gas leak detectors, while valuable, lack the connectivity and advanced functionalities offered by IoT systems. Here’s how IoT elevates gas leak detection:

- Enhanced Scalability: Multiple sensors can be integrated into a single system, enabling comprehensive monitoring across larger spaces. This is particularly beneficial for industrial settings or large buildings.

- Remote Monitoring and Control: The ability to receive real-time alerts and access data remotely provides greater control and facilitates faster intervention in case of a leak.

- Data Analytics: Cloud-based data storage allows for historical analysis of gas levels. This can help identify patterns or predict potential leaks, leading to preventative measures.

- Improved Response Time: Automated actions like shutting off gas valves ensure a faster and more efficient response to leaks, minimizing potential damage.

Beyond Homes: Applications in Diverse Settings

While domestic settings benefit significantly from IoT-enabled gas leak detection, the technology’s reach extends far beyond homes. Here are some additional applications:

- Industrial Facilities: Factories and plants that handle hazardous gases can leverage these systems for enhanced safety protocols.

- Commercial Buildings: Offices, restaurants, and other commercial spaces can benefit from real-time monitoring and automated shut-off features.

The Future of IoT-based Gas Leak Detection

As IoT technology continues to evolve, so too will gas leak detection systems. We can expect advancements in:

- Sensor Sensitivity: More sensitive sensors will enable even earlier and more accurate leak detection.

- Machine Learning Integration: Machine learning algorithms could be used to differentiate between harmless fluctuations and actual leaks, minimizing false positives.

Conclusion

IoT-enabled gas leak detection systems offer a powerful solution for safeguarding lives and property. By leveraging real-time data, remote monitoring, and automated responses, these systems provide a significant leap forward in ensuring safety within homes, industries, and beyond. As technology progresses, we can expect even more sophisticated and reliable gas leak detection solutions in the future.