In today’s increasingly digitized industrial landscape, monitoring, conserving, and optimizing resources is no longer just a smart idea it’s a necessity. One resource that often flies under the radar is steam condensate. Steam systems are everywhere in manufacturing, food processing, chemical plants, textile production, and more and they’re notoriously energy-intensive. That’s where CST’s Condensate Recovery Meter CRM 485R comes into play.

But wait why stop monitoring when you can make it smarter? That’s exactly what happens when you integrate the CRM 485R with an IoT Gateway. This blog dives into what the CRM 485R is, how the IoT integration works, and the real-world value it brings to industries looking to level up their energy efficiency game.

Table of Contents

- What Is the CRM 485R?

- Key Features of CRM 485R:

- Why Integrate It with an IoT Gateway?

- The Integration Architecture (A Simple Overview)

- Real-World Use Case: Industrial Steam Plant

- Benefits of This Integration

- IoT Gateway Options for CRM 485R

- Data You Can Track from CRM 485R

- Integration Tips & Best Practices

- Why HashStudioz?

- Final Thoughts

What Is the CRM 485R?

The CRM 485R is a condensate recovery meter designed and manufactured by CST Instruments. In simple terms, it’s a smart device that helps measure how much condensate is being returned to the boiler system. Why is that important?

Because recovering condensate:

- Saves water

- Conserves heat energy

- Reduces fuel consumption

- Minimizes chemical use

- Extends equipment life

The CRM 485R uses high-accuracy sensors and supports RS-485 Modbus RTU communication, making it suitable for modern industrial automation systems.

Key Features of CRM 485R:

- Non-intrusive clamp-on design

- RS-485 Modbus communication

- Measures flow rate, temperature, and volume

- Compact, rugged, and maintenance-free

- Ideal for harsh industrial environments

Why Integrate It with an IoT Gateway?

Here’s the fun part imagine if all the condensate recovery data could be:

- Collected in real-time

- Pushed to the cloud

- Monitored from anywhere in the world

- Used for predictive maintenance

- Integrated with energy management dashboards

That’s exactly what IoT integration enables.

An IoT gateway acts as a bridge between your field devices (like the CRM 485R) and the internet/cloud. It collects Modbus data from the CRM 485R, translates it into a cloud-readable format (like MQTT/HTTP), and pushes it to your preferred platform AWS IoT, Azure IoT Hub, Google Cloud, or even a custom dashboard.

The Integration Architecture (A Simple Overview)

Let’s break down how the CRM 485R connects with an IoT Gateway in a typical setup:

- Physical Connection:

- The CRM 485R has an RS-485 output.

- It connects to the RS-485 port of the IoT gateway using a twisted-pair cable.

- The CRM 485R has an RS-485 output.

- Protocol Translation:

- The IoT gateway reads Modbus RTU data from the CRM.

- It parses parameters like flow rate, temperature, total volume, etc.

- The IoT gateway reads Modbus RTU data from the CRM.

- Data Processing:

- The gateway processes raw data and applies thresholds or filters if needed.

- It may aggregate or normalize values before sending them upstream.

- The gateway processes raw data and applies thresholds or filters if needed.

- Cloud Communication:

- The processed data is published to the cloud via protocols like MQTT, HTTP, or CoAP.

- Authentication and encryption (e.g., TLS) ensure secure data transmission.

- The processed data is published to the cloud via protocols like MQTT, HTTP, or CoAP.

- Visualization and Analytics:

- Data is stored and displayed in a dashboard.

- Users can set alerts, generate reports, and run analytics.

- Data is stored and displayed in a dashboard.

Real-World Use Case: Industrial Steam Plant

Let’s say you run a large textile manufacturing plant that heavily relies on steam. Traditionally, you’d check condensate levels once in a while and maybe log them manually. That’s inefficient and ripe for errors.

But once you install CRM 485R meters on your condensate return lines and link them to an IoT gateway, here’s what changes:

- You get real-time visibility of how much condensate is being recovered at each point.

- If the recovery rate drops, you get automated alerts that maybe there’s a leak or block.

- You can track trends over days, weeks, or months to optimize operations.

- The system can automatically feed this data into your Energy Management System (EMS) or SCADA.

That’s not just automation. That’s smart industrial monitoring.

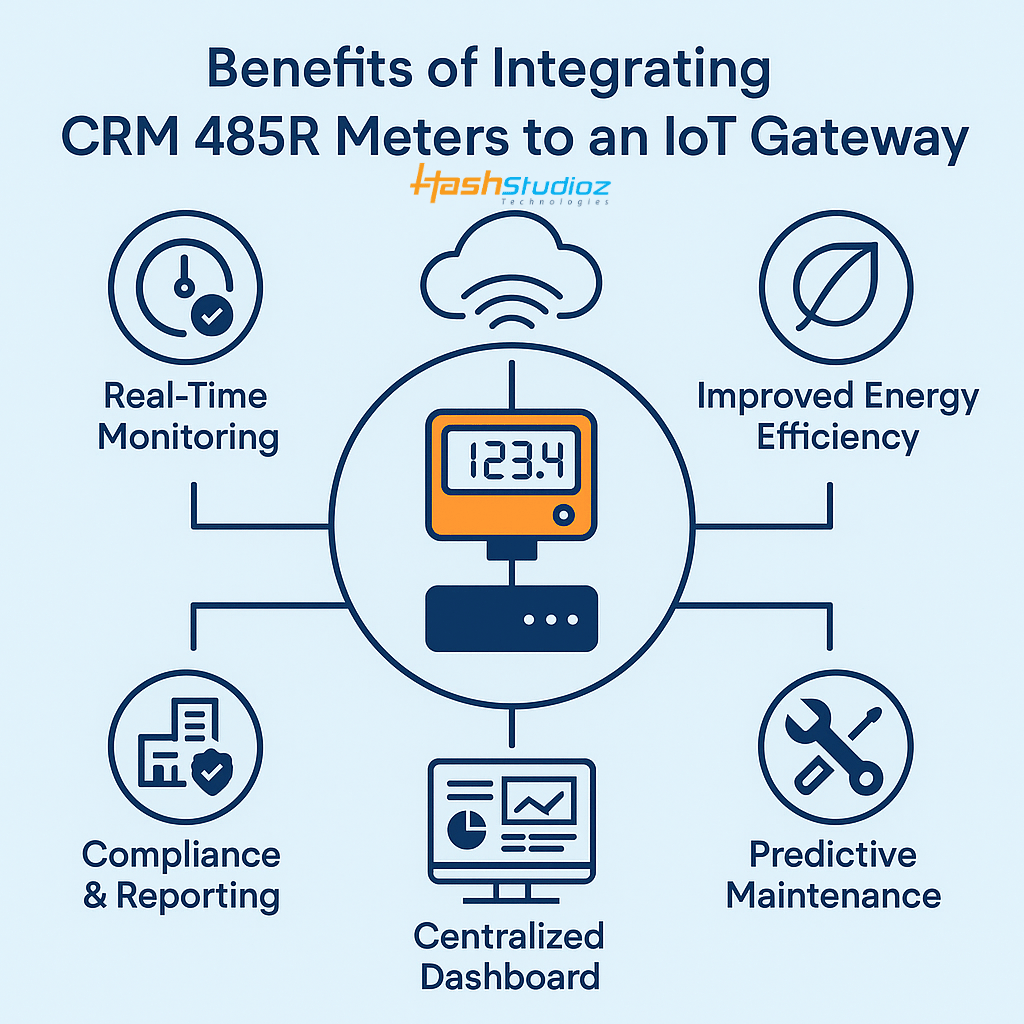

Benefits of This Integration

Let’s get practical. Why should industries care about connecting their CRM 485R meters to an IoT gateway?

Real-Time Monitoring

Instead of manually checking meters, engineers can access readings 24/7 from their phones or laptops.

Improved Energy Efficiency

Condensate is loaded with energy. Recovering and reusing it efficiently reduces boiler fuel costs.

Predictive Maintenance

Spikes or drops in flow rate? Unusual temperatures? The system can flag problems before they become failures.

Compliance & Reporting

Having a cloud-based dashboard helps with regulatory audits, ESG reporting, and internal reviews.

Centralized Dashboard

Even if you have 50 CRM meters across 5 factories you can manage them all from a single dashboard.

Read Also: IoT Energy Meter Gateway – Transforming Energy Monitoring with IoT

IoT Gateway Options for CRM 485R

When choosing an IoT gateway, make sure it supports RS-485 Modbus RTU, has cloud connectivity (Ethernet/Wi-Fi/4G), and can handle protocol translation.

Some popular options:

- Advantech UNO series

- Milesight UG65 or UG67

- Elipse Gateway

- Raspberry Pi with Modbus hat (for DIY setups)

- Arduino or ESP32 (if the budget is tight)

You can even use Node-RED or Python scripts on these gateways to parse and push data to your cloud server.

Data You Can Track from CRM 485R

Here’s what kind of data typically flows from the CRM 485R to your IoT system:

- Instantaneous Flow Rate (L/min or m³/hr)

- Temperature of the condensate

- Total Volume Recovered (m³)

- Hourly/Daily Recovery Trends

- Alarms for Low Flow or High Temperature

This data can be combined with other utilities like steam generation data, water makeup data, etc. to give a 360° view of your steam system efficiency.

Integration Tips & Best Practices

Here are some things to keep in mind:

- Proper Termination: Use 120-ohm resistors for RS-485 line termination to prevent signal reflection.

- Data Polling: Set polling intervals based on process needs 5–10 seconds is usually fine.

- Security: Use firewalls, VPNs, and encrypted data channels for secure cloud communication.

- Offline Buffering: Use gateways that can buffer data during internet downtime and upload once back online.

- Alerts & Thresholds: Set meaningful thresholds, for example, flow < 10 L/min triggers a maintenance alert.

Why HashStudioz?

At HashStudioz Technologies, we’re more than just IoT developers we’re your technology partners. With proven experience in building end-to-end IoT ecosystems for industries, our team ensures smooth deployment, zero data loss, and scalable infrastructure.

Whether it’s retrofitting your current system or building something from scratch, we deliver smart, secure, and scalable IoT solutions that just work.

Final Thoughts

Steam systems can be silent profit-drainers if not monitored closely. With the CRM 485R integrated through HashStudioz IoT Gateways, you bring intelligence to your condensate recovery improving efficiency, minimizing waste, and driving sustainability.

Want to make your steam system smarter? Let’s talk.