Edge computing is revolutionizing Industrial IoT (IIoT) by bringing processing power closer to the source of data generation. Unlike traditional cloud-based systems, edge computing enables real-time analytics and decision-making at the device level. This shift is particularly crucial in industries where low latency, high reliability, and enhanced security are essential.

- By 2025, over 75% of industrial data will be processed at the edge .

- The global edge computing market is expected to reach $61.14 billion by 2028.

Table of Contents

- Understanding Modbus and MQTT Protocols

- What is a Modbus to MQTT Gateway?

- RS485 IoT Gateway: Bridging Legacy Systems with Modern IoT

- How Edge Computing Enhances Modbus to MQTT Gateway Functionality

- Key Benefits of Using Edge Computing with Modbus to MQTT Gateways

- Challenges and Solutions in Implementing Modbus to MQTT Gateways at the Edge

- Security Considerations for Modbus to MQTT and RS485 IoT Gateways

- Real-World Use Cases of Edge Computing with Modbus to MQTT Gateways

- Best Practices for Deploying an Edge Computing-Based Modbus to MQTT Gateway

- Conclusion

- FAQs

- Q1: What is the primary function of a Modbus to MQTT gateway?

- Q2: Why is edge computing important for industrial IoT?

- Q3: How does an RS485 IoT gateway enhance Modbus communication?

- Q4: What security measures should be implemented for Modbus to MQTT gateways?

- Q5: Can edge computing replace cloud computing in industrial IoT?

Understanding Modbus and MQTT Protocols

Industrial automation and IIoT (Industrial Internet of Things) rely heavily on efficient and standardized communication protocols to enable seamless data exchange between devices, sensors, and cloud platforms. Two of the most widely used protocols in this domain are Modbus and MQTT. Understanding how they function is essential for implementing a Modbus to MQTT gateway effectively.

Modbus Protocol

Developed in 1979 by Modicon (now Schneider Electric), Modbus is one of the most widely used industrial communication protocols. It was initially designed for programmable logic controllers (PLCs) to facilitate communication between electronic devices in industrial automation and SCADA (Supervisory Control and Data Acquisition) systems.

Key Features of Modbus:

- Open Standard: Free to use and widely adopted across industries.

- Master-Slave Architecture: One master device (PLC, SCADA system, or industrial controller) communicates with multiple slave devices (sensors, actuators, or remote I/O units).

- Supports Multiple Communication Interfaces:

- RS485 IoT gateway (Most common for industrial applications)

- RS232 (Short-range communication)

- Modbus TCP/IP (Ethernet-based for modern applications)

- Simple and Efficient: Uses a straightforward request-response mechanism for data exchange.

- Data Representation: Exchanges data in registers, which can store values such as temperature, pressure, or system status.

Modbus Communication Modes:

- Modbus RTU (Remote Terminal Unit):

- Uses binary encoding for compact and efficient communication.

- Runs over RS485 or RS232 serial interfaces.

- Ideal for low-power, low-bandwidth industrial applications.

- Modbus ASCII:

- Similar to RTU but uses ASCII encoding, making it human-readable.

- Less efficient than Modbus RTU due to increased data overhead.

- Modbus TCP/IP:

- Uses Ethernet for communication.

- Supports faster data exchange and integrates well with modern network infrastructure.

- Allows remote monitoring and control via industrial cloud systems.

MQTT Protocol

MQTT (Message Queuing Telemetry Transport) is a lightweight, publish-subscribe messaging protocol designed for fast and efficient communication between IoT devices and cloud platforms. Developed by IBM in the 1990s, MQTT is now widely used in Industrial IoT (IIoT) applications for transmitting sensor data, machine status, and control commands.

Key Features of MQTT:

- Low Bandwidth Consumption: Optimized for constrained networks, making it ideal for IIoT applications.

- Efficient and Scalable: Works well with a large number of connected devices.

- Reliable Data Transmission: Supports QoS (Quality of Service) levels to ensure message delivery.

- Lightweight Messaging: Uses a small packet size, making it suitable for low-power devices.

- Cloud Integration: Easily connects industrial devices to cloud platforms like AWS IoT, Azure IoT Hub, and Google Cloud IoT.

MQTT Communication Model:

Unlike Modbus, which follows a master-slave model, MQTT uses a publish-subscribe model:

- Publisher: The device or sensor that sends data.

- Broker: The central server that receives, filters, and forwards messages.

- Subscriber: The device or application that receives relevant data.

MQTT QoS (Quality of Service) Levels:

MQTT ensures message reliability using three QoS levels:

- QoS 0 (At most once): Fire-and-forget messaging with no guarantee of delivery.

- QoS 1 (At least once): Ensures that the message is received at least once but may result in duplicates.

- QoS 2 (Exactly once): Guarantees message delivery without duplication, but with additional overhead.

Why Integrate Modbus with MQTT?

Since Modbus is widely used in legacy industrial automation systems, while MQTT is essential for modern IoT cloud integration, a Modbus to MQTT gateway serves as a bridge to connect traditional industrial devices with cloud-based IoT platforms. This enables real-time monitoring, predictive maintenance, and remote management of industrial equipment.

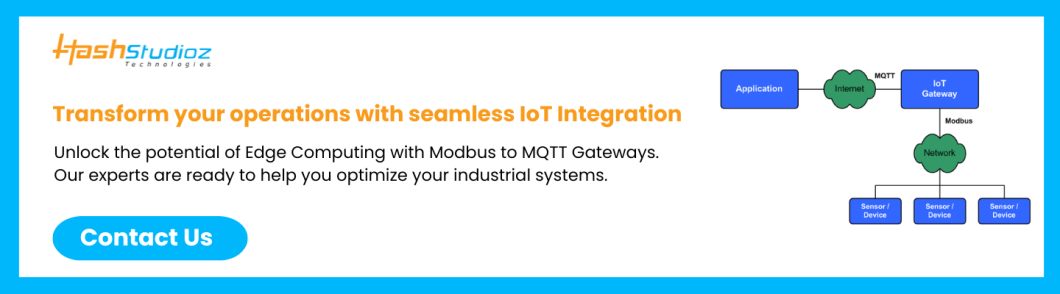

What is a Modbus to MQTT Gateway?

A Modbus to MQTT gateway is a crucial device that acts as a bridge between Modbus-based industrial equipment and MQTT-enabled IoT or cloud platforms. This gateway translates Modbus communication protocols (RTU/TCP) into MQTT messages, enabling seamless integration of legacy industrial systems with modern edge computing and cloud-based IoT infrastructures.

Why is a Modbus to MQTT Gateway Necessary?

Many industrial automation systems rely on Modbus protocol, which operates on serial (RS485, RS232) or Ethernet (Modbus TCP) communication. However, modern Industrial IoT (IIoT) platforms and cloud systems use MQTT for efficient, low-bandwidth, real-time data exchange. A Modbus to MQTT gateway allows these two different technologies to communicate, ensuring industrial devices can be monitored and controlled remotely.

Key Features of a Modbus to MQTT Gateway

- Protocol Translation: Converts Modbus RTU/TCP data into MQTT topics, making industrial devices compatible with cloud applications.

- Bidirectional Communication: Enables both data transmission and control, allowing IoT platforms to send commands back to industrial devices.

- Localized Edge Processing: Reduces dependency on centralized cloud systems by processing data locally on the RS485 IoT gateway, improving efficiency and reducing latency.

- Multiple Connectivity Options: Supports communication via RS485, RS232, Ethernet (TCP/IP), or Wi-Fi.

- Optimized Data Handling: Uses MQTT’s publish-subscribe model to ensure only relevant data is transmitted, reducing bandwidth usage.

- Integration with Cloud Platforms: Connects seamlessly with AWS IoT, Azure IoT Hub, Google Cloud IoT, and private industrial cloud solutions.

- Enhanced Security: Implements TLS encryption, authentication, and authorization mechanisms to ensure secure data exchange between industrial devices and cloud applications.

- Real-Time Monitoring & Control: Enables real-time data visualization, anomaly detection, and predictive maintenance in industrial settings.

How Does a Modbus to MQTT Gateway Work?

- Data Collection: The gateway reads sensor data from Modbus RTU (RS485) or Modbus TCP devices.

- Protocol Conversion: Translates Modbus register values into MQTT topics (e.g., temperature, pressure, or motor speed).

- Data Publishing: Sends MQTT messages to an MQTT broker for distribution to cloud applications or edge computing platforms.

- Command Reception: If required, the gateway receives MQTT commands from the cloud and converts them back into Modbus commands for the industrial device.

Benefits of Using a Modbus to MQTT Gateway in Industrial IoT

- Seamless integration of legacy Modbus devices into modern IIoT frameworks.

- Improved operational efficiency with real-time monitoring and analytics.

- Reduced cloud bandwidth costs by handling processing locally.

- Increased scalability, enabling thousands of industrial devices to connect securely.

RS485 IoT Gateway: Bridging Legacy Systems with Modern IoT

An RS485 IoT gateway is a vital component in industrial automation, enabling legacy Modbus RTU devices to connect with modern IP-based networks and cloud platforms. By bridging the gap between traditional serial communication (RS485/RS232) and IoT protocols like MQTT, this gateway ensures seamless data exchange, remote monitoring, and edge computing capabilities for industrial environments.

Why RS485 IoT Gateway Matters?

Many legacy industrial devices use the Modbus RTU protocol over RS485, a reliable serial communication standard. However, modern IoT systems primarily utilize Ethernet, Wi-Fi, or cellular networks for real-time data exchange and cloud integration. An RS485 IoT gateway serves as the intermediary, enabling legacy devices to function in modern IIoT ecosystems.

Key Advantages of an RS485 IoT Gateway

1. Long-Distance Communication

- RS485 supports communication up to 1200 meters (4000 feet) without significant signal loss.

- Ideal for large industrial plants, manufacturing units, and remote monitoring applications.

2. High Noise Immunity

- RS485 is differential (balanced) signaling, making it highly resistant to electromagnetic interference (EMI).

- Works efficiently in noisy industrial environments with heavy machinery, motors, and other electrical disturbances.

3. Seamless Edge Computing Integration

- The RS485 IoT gateway enables local data processing before sending it to the cloud.

- Reduces bandwidth usage, lowers latency, and allows for real-time decision-making in industrial applications.

4. Multi-Device Connectivity

- Supports multi-drop communication, allowing multiple Modbus RTU devices to connect on a single RS485 bus.

- Efficient for factories, power plants, and smart grids where multiple sensors and actuators are deployed.

5. Protocol Conversion for IoT Integration

- Converts RS485 (Modbus RTU) data into Ethernet, Wi-Fi, MQTT, or HTTP for seamless integration with IIoT platforms.

- Enables connection with AWS IoT, Azure IoT Hub, Google Cloud IoT, and private industrial cloud networks.

6. Security and Remote Management

- Many RS485 IoT gateways include encryption, authentication, and firewall features for secure industrial communication.

- Supports remote firmware updates, configuration, and troubleshooting, reducing on-site maintenance efforts.

How an RS485 IoT Gateway Works?

- Collects Data: Reads sensor/machine data from Modbus RTU devices over RS485 communication.

- Protocol Conversion: Converts Modbus RTU data into IP-based protocols like MQTT, HTTP, or TCP/IP.

- Edge Processing: Filters, compresses, and processes raw industrial data locally before sending it to the cloud.

- Cloud Communication: Transmits processed data to MQTT brokers, cloud platforms, or industrial SCADA systems.

- Remote Commands & Control: Receives control commands from the cloud and translates them into Modbus RTU signals to control industrial devices.

Use Cases of RS485 IoT Gateways in Industry

- Smart Factories & Industry 4.0 → Connects legacy PLCs and sensors with modern IoT analytics.

- Renewable Energy → Monitors solar panels, wind turbines, and battery management systems remotely.

- Smart Grids & Utilities → Integrates power meters and distribution networks with cloud-based energy management systems.

- Oil & Gas → Enables real-time monitoring of pipelines, pressure levels, and remote field assets.

How Edge Computing Enhances Modbus to MQTT Gateway Functionality

Edge computing significantly improves the functionality of a Modbus to MQTT gateway by processing data closer to the source, reducing latency, optimizing bandwidth usage, and enhancing security. Instead of sending raw industrial data directly to the cloud, an edge-enabled RS485 IoT gateway processes and filters the data locally, ensuring faster decision-making and reduced network strain.

1. Reduced Latency: Faster Decision-Making

One of the biggest advantages of edge computing is its ability to process data in real-time without relying on a centralized cloud system.

- Why It Matters?

- Industrial applications require instant response times to prevent failures, optimize processes, and improve efficiency.

- Traditional cloud-based systems introduce latency due to the time it takes for data to travel back and forth.

- How the Modbus to MQTT Gateway Benefits?

- Local data processing allows real-time anomaly detection and preventive actions.

- Decisions are made in milliseconds, rather than seconds or minutes, preventing costly delays in critical systems.

- Example: In a smart factory, an edge-enabled Modbus to MQTT gateway can immediately detect temperature fluctuations in industrial machinery and trigger cooling mechanisms before overheating occurs.

2. Bandwidth Optimization: Efficient Data Transmission

Cloud computing requires constant upstream and downstream data flow, leading to high network congestion and bandwidth costs. Edge computing helps filter, compress, and optimize industrial data before transmitting it to the cloud.

- Why It Matters?

- Industrial plants generate massive amounts of sensor data.

- Sending all raw data to the cloud consumes excessive bandwidth, increasing costs and slowing down processing speeds.

- How the Modbus to MQTT Gateway Benefits?

- The RS485 IoT gateway pre-processes and filters irrelevant data, sending only meaningful insights to the cloud.

- Reduces network congestion by eliminating redundant or unnecessary data points.

- Example: A Modbus to MQTT gateway in a wind farm can analyze wind speed data locally and only send alerts when speeds exceed safety thresholds, reducing unnecessary cloud communication.

3. Enhanced Security: Protecting Industrial Networks

Security is a top priority for industrial IoT (IIoT) applications. Edge computing improves security by processing sensitive data locally, reducing exposure to cyber threats that are common in cloud-based systems.

- Why It Matters?

- Cyberattacks on cloud-based industrial networks can compromise sensitive machine data.

- Direct cloud transmission exposes data to man-in-the-middle attacks, data breaches, and unauthorized access.

- How the Modbus to MQTT Gateway Benefits?

- The RS485 IoT gateway encrypts data locally, ensuring only authenticated messages are sent to the cloud.

- Reduces reliance on centralized cloud servers, minimizing attack surfaces.

- Example: In an oil refinery, an edge-enabled Modbus to MQTT gateway can process pipeline pressure data locally, triggering safety mechanisms on-site without exposing critical infrastructure data to cloud vulnerabilities.

Key Benefits of Using Edge Computing with Modbus to MQTT Gateways

Integrating edge computing with a Modbus to MQTT gateway offers a transformative advantage for industrial automation by enabling real-time data processing, predictive analytics, and efficient IoT connectivity. By leveraging edge intelligence, industries can enhance operational efficiency, reduce costs, and seamlessly integrate legacy Modbus-based systems with modern cloud platforms.

1. Real-time Decision Making: Predictive Maintenance & Analytics

One of the most significant benefits of edge computing is its ability to process and analyze data locally, enabling real-time decision-making without relying on a centralized cloud.

- Why It Matters?

- Industrial machines require immediate response mechanisms to prevent failures, reduce downtime, and optimize performance.

- Predictive maintenance relies on real-time anomaly detection to anticipate failures before they occur.

- How Edge Computing Enhances Modbus to MQTT Gateway Functionality?

- Processes sensor data at the edge, identifying patterns that indicate wear, tear, or malfunction.

- Triggers automated maintenance alerts before a failure occurs, reducing costly downtimes.

- Example: In a manufacturing plant, an edge-enabled RS485 IoT gateway can monitor motor vibration levels and automatically schedule maintenance when an anomaly is detected, preventing unplanned shutdowns.

2. Increased Operational Efficiency: Downtime Reduction & Process Automation

Industries rely on automated workflows and reduced downtimes to maintain productivity. Edge-enabled Modbus to MQTT gateways ensure continuous data flow, even if cloud connectivity is disrupted.

- Why It Matters?

- Traditional cloud-based processing can introduce delays, impacting automated decision-making.

- Machine failures and unexpected downtime cost industries millions in lost productivity.

- How Edge Computing Enhances Modbus to MQTT Gateway Functionality?

- Continues processing data locally, ensuring that automation processes remain uninterrupted.

- Minimizes dependency on cloud-based analytics, making industrial operations faster and more reliable.

- Example: In a smart factory, an RS485 IoT gateway connected to robotic arms can locally process movement commands, ensuring seamless production flow even if the cloud server goes offline.

3. Better Resource Utilization: Optimized Storage & Computational Overhead

Cloud storage and computation costs increase exponentially as the number of connected industrial devices grows. Edge computing helps reduce these costs by processing and filtering data before transmission.

- Why It Matters?

- Sending raw Modbus RTU data directly to the cloud results in excessive bandwidth consumption.

- High computational workloads on the cloud increase latency and operational costs.

- How Edge Computing Enhances Modbus to MQTT Gateway Functionality?

- Filters and compresses industrial data at the edge, reducing storage and processing requirements in the cloud.

- Transmits only meaningful insights instead of bulk raw data, optimizing network efficiency.

- Example: A Modbus to MQTT gateway in a power grid can analyze real-time energy consumption data at the edge and only send summarized insights to the cloud, reducing unnecessary data transmission.

4. Seamless Legacy Integration: Connecting Modbus Devices to IoT Platforms

Most industrial facilities still operate legacy Modbus RTU devices that were not originally designed for cloud communication. Edge-enabled Modbus to MQTT gateways act as a bridge between traditional Modbus networks and modern IoT platforms.

- Why It Matters?

- Many industrial machines and sensors use RS485/Modbus RTU, which lacks native cloud connectivity.

- Upgrading entire systems to new IoT-enabled devices is expensive and impractical.

- How Edge Computing Enhances Modbus to MQTT Gateway Functionality?

- Translates Modbus RTU/TCP data into MQTT topics, making it compatible with modern IoT frameworks.

- Locally processes Modbus data before sending it to cloud dashboards, SCADA systems, or AI-driven analytics platforms.

- Example: A water treatment plant can continue using its legacy Modbus-based sensors by integrating them with an edge-enabled RS485 IoT gateway, enabling remote monitoring via MQTT on cloud dashboards.

Challenges and Solutions in Implementing Modbus to MQTT Gateways at the Edge

While Modbus to MQTT gateways offer significant advantages in industrial automation and IIoT (Industrial Internet of Things), their implementation at the edge comes with several challenges. These include legacy device compatibility issues, data overload, security concerns, and complex deployment. However, with RS485 IoT gateways and intelligent edge computing solutions, these challenges can be effectively addressed.

1. Legacy Device Compatibility

Challenge:

Many industrial systems still operate on legacy Modbus RTU/TCP devices, which were not originally designed for cloud connectivity. These systems use RS485 serial communication and lack native support for modern IoT protocols like MQTT.

Solution:

- RS485 IoT gateways act as protocol converters, enabling seamless communication between legacy Modbus RTU devices and cloud-based MQTT platforms.

- These gateways translate Modbus RTU/TCP data into MQTT messages, making old industrial equipment compatible with new-age IoT ecosystems.

- Example: A manufacturing plant with decades-old Modbus-based PLCs (Programmable Logic Controllers) can integrate them into an IoT platform using a Modbus to MQTT gateway without replacing existing infrastructure.

2. Data Overload

Challenge:

Industrial environments generate massive volumes of data from multiple sensors, PLCs, and control systems. Sending raw data directly to the cloud can cause network congestion, increased storage costs, and slower processing speeds.

Solution:

- Implement intelligent filtering and preprocessing at the edge.

- An edge-enabled Modbus to MQTT gateway can analyze and filter unnecessary data before transmission, ensuring only relevant insights reach the cloud.

- Use data compression techniques to reduce the size of MQTT messages without compromising critical information.

- Example: In a wind farm, rather than sending continuous raw data from temperature sensors, an RS485 IoT gateway can aggregate readings, detect anomalies, and only send alerts when necessary.

3. Security Risks

Challenge:

With data moving from edge devices to cloud servers, there is an increased risk of cyberattacks, unauthorized access, and data breaches. Modbus itself lacks built-in encryption, making it susceptible to man-in-the-middle attacks when connected to the internet.

Solution:

- Employ end-to-end encryption in MQTT communication to secure data transmission.

- Use TLS/SSL encryption for MQTT messages to prevent eavesdropping and unauthorized access.

- Implement authentication mechanisms, such as username-password authentication or X.509 certificates, to ensure only authorized devices can communicate.

- Example: A Modbus to MQTT gateway in a smart grid can use AES-256 encryption to protect power distribution data from cyber threats while sending it to the cloud.

4. Complex Deployment

Challenge:

Setting up Modbus to MQTT gateways at the edge can be technically challenging, requiring manual configuration, network integration, and compatibility checks. This can lead to deployment delays and increased maintenance efforts.

Solution:

- Use plug-and-play edge gateways that support auto-configuration for quick setup.

- Deploy pre-configured RS485 IoT gateways with built-in Modbus-MQTT conversion capabilities.

- Example: In a remote oil rig, a pre-configured Modbus to MQTT gateway with auto-detection features can be deployed without requiring an on-site IT team, reducing setup complexity.

Security Considerations for Modbus to MQTT and RS485 IoT Gateways

As industrial environments become more connected, Modbus to MQTT gateways and RS485 IoT gateways introduce new cybersecurity risks. These devices bridge legacy industrial protocols with modern cloud-based IoT platforms, making them prime targets for cyber threats if not properly secured. Implementing strong security measures ensures data integrity, device authentication, and protection against unauthorized access.

1. Secure MQTT Communication: Implement TLS Encryption

Security Risk:

MQTT is a lightweight protocol, but by default, it lacks encryption, making it vulnerable to man-in-the-middle attacks, data interception, and unauthorized modifications during transmission.

Security Solution:

- Enable Transport Layer Security (TLS 1.2/1.3) for end-to-end encryption between the Modbus to MQTT gateway and the cloud broker.

- Use secure MQTT ports (8883 instead of 1883) to prevent unauthorized access.

- Example: A Modbus to MQTT gateway transmitting real-time energy consumption data from industrial machines can encrypt MQTT messages using TLS, ensuring that data remains protected during transmission.

2. User Authentication: Use MQTT Authentication Mechanisms

Security Risk:

Without proper authentication, any unauthorized device could potentially connect to the MQTT broker, intercepting sensitive industrial data or injecting malicious commands.

Security Solution:

- Implement username-password authentication for all devices communicating via MQTT.

- Use client certificates (X.509) for mutual authentication to verify both the gateway and MQTT broker identities.

- Example: A secure RS485 IoT gateway in an oil refinery can require device authentication before sending Modbus RTU data to the cloud, preventing unauthorized data access.

3. Access Control: Define Strict Role-Based Access Policies

Security Risk:

If all connected devices and users have unrestricted access, an attacker gaining entry could control critical industrial operations or manipulate sensitive data.

Security Solution:

- Implement Role-Based Access Control (RBAC) to restrict access based on user roles and privileges.

- Use access control lists (ACLs) to define who can publish or subscribe to specific MQTT topics.

- Example: In a smart factory, a Modbus to MQTT gateway can enforce RBAC, allowing only authorized users to modify machine settings while keeping monitoring roles restricted to data access only.

Real-World Use Cases of Edge Computing with Modbus to MQTT Gateways

Edge computing, when combined with Modbus to MQTT gateways, enables efficient data processing at the source, reducing latency and enhancing decision-making capabilities. By processing data close to the point of collection, industries can achieve real-time insights, improved efficiency, and better scalability. Here are some key real-world use cases demonstrating the power of this integration.

1. Smart Manufacturing

In smart manufacturing, predictive maintenance and real-time sensor monitoring are essential for reducing downtime and increasing operational efficiency. By integrating edge computing with Modbus to MQTT gateways, manufacturers can achieve faster data processing, enabling immediate action on potential issues.

How It Works:

- Sensors on machines, PLCs, and motors collect data like temperature, vibration, and pressure.

- The Modbus to MQTT gateway communicates this data to the cloud, converting Modbus RTU into MQTT messages for remote monitoring.

- With edge computing, this data is processed locally before being sent to the cloud, allowing immediate diagnostics and predictive maintenance based on real-time insights.

Benefits:

- Reduced downtime through early detection of faults and anomalies.

- Minimized operational costs by addressing issues proactively rather than reactively.

- Improved asset life-cycle management by monitoring critical machinery.

Example:

In a smart manufacturing plant, vibration sensors on motors send data via Modbus to MQTT gateways. Local edge processing analyzes this data in real time, alerting the maintenance team about potential failures before they occur, reducing costly downtime.

2. Smart Grid Management

In smart grid management, efficiently managing distributed energy resources (DERs) like solar panels, wind turbines, and batteries is crucial for ensuring energy reliability and efficiency. The integration of edge computing with Modbus to MQTT gateways facilitates low-latency data processing, making grid operations smarter and more responsive.

How It Works:

- Energy meters, solar inverters, and batteries communicate via Modbus RTU to local gateways.

- The Modbus to MQTT gateway sends this data in MQTT format to cloud-based systems, enabling real-time monitoring and control.

- With edge computing, critical data such as voltage, current, and power consumption is processed on-site, optimizing energy distribution and minimizing delays in communication.

Benefits:

- Real-time energy optimization by monitoring and controlling DERs more efficiently.

- Enhanced grid stability with immediate reaction to fluctuations or faults.

- Improved efficiency in energy generation, consumption, and storage.

Example:

A smart grid uses edge computing to monitor solar power output and battery charge levels in real time. By using Modbus to MQTT gateways, the system can dynamically adjust energy flow based on local weather conditions and grid demand, improving energy efficiency and reducing transmission losses.

3. Oil and Gas Monitoring

In oil and gas monitoring, safety and fault detection are top priorities. Real-time monitoring of pipeline conditions, pumps, and valves is critical for preventing accidents and minimizing environmental impact. The integration of Modbus to MQTT gateways with edge computing enables instant detection of faults and anomalies in this high-risk sector.

How It Works:

- Modbus RTU-enabled sensors installed on pipelines and processing equipment measure parameters like pressure, temperature, and flow rate.

- The Modbus to MQTT gateway facilitates data transmission to cloud platforms in MQTT format, enabling remote monitoring.

- Edge computing processes the data locally, performing real-time analysis to detect leaks, pressure drops, and other faults before they escalate.

Benefits:

- Enhanced safety by detecting faults or anomalies in real time, preventing hazardous situations.

- Faster response times with on-site processing, reducing the risk of accidents.

- Increased operational efficiency by optimizing pipeline performance and minimizing downtime.

Example:

An oil refinery uses edge computing to monitor pipeline pressure and temperature via Modbus sensors. The Modbus to MQTT gateway ensures real-time data transmission and local processing. If a pressure drop or leak is detected, the system immediately alerts operators to take corrective actions, avoiding potential disasters.

Best Practices for Deploying an Edge Computing-Based Modbus to MQTT Gateway

Deploying an edge computing-based Modbus to MQTT gateway is a critical step in ensuring seamless communication between legacy industrial devices and modern IoT systems. By processing data at the edge, businesses can achieve low-latency communication, real-time analytics, and improved system efficiency. Below are best practices to follow when deploying a Modbus to MQTT gateway with edge computing capabilities to ensure optimal performance, reliability, and security.

1. Choose the Right Hardware: Ensure Compatibility with Modbus RTU/TCP

Why It Matters:

The hardware used for the Modbus to MQTT gateway plays a crucial role in ensuring that data transmission is reliable, secure, and efficient. Choosing hardware that is compatible with Modbus RTU/TCP is essential for seamless integration between legacy devices and modern IoT networks.

Best Practices:

- Evaluate Compatibility: Ensure the gateway supports both Modbus RTU (serial communication) and Modbus TCP (Ethernet-based communication) protocols, depending on the types of devices in use.

- Processor and Memory: The gateway should have sufficient processing power and memory to handle local data processing, especially if the system requires complex data filtering or analytics at the edge.

- Connectivity Options: Choose hardware with multiple communication options, including RS485, Wi-Fi, and Ethernet, for flexibility in connecting devices across different network types.

- Scalability: Opt for hardware that supports easy scalability, allowing for future expansion as the number of connected devices grows.

Example:

In a smart factory, a gateway compatible with both Modbus RTU for legacy equipment and Modbus TCP for newer devices ensures seamless data flow across the entire system, with the edge computing capability handling preprocessing and analytics locally.

2. Optimize Data Filtering: Reduce Unnecessary Cloud Transmission

Why It Matters:

One of the main advantages of edge computing is the ability to process data locally, which helps to reduce the load on cloud servers and minimize network congestion. Properly optimizing data filtering ensures that only relevant data is sent to the cloud, improving efficiency and reducing costs associated with data transmission and storage.

Best Practices:

- Implement Intelligent Filtering at the Edge: Set up edge devices to process and filter out unnecessary or redundant data before sending it to the cloud. For example, if the data values remain constant over time, they need not be sent continuously to the cloud.

- Data Aggregation: Instead of sending every data point individually, aggregate data in batches to reduce the frequency of transmissions.

- Event-Based Reporting: Use an event-driven model where data is transmitted only when certain conditions or thresholds are met (e.g., an anomaly is detected in equipment performance).

- Edge Preprocessing: Perform initial data validation, cleaning, and analysis at the edge to ensure only meaningful, actionable insights are forwarded to the cloud.

Example:

In an oil pipeline monitoring system, edge devices filter out normal pressure readings and only send alerts or irregular data to the cloud for further analysis, ensuring that the network is not overwhelmed with redundant data.

3. Implement Redundant Communication: Ensure Data Integrity in Case of Network Failures

Why It Matters:

Industrial environments often experience network instability or temporary communication failures. To ensure continuous operation and avoid data loss, it’s essential to implement redundant communication paths and mechanisms that provide failover options during network disruptions.

Best Practices:

- Dual Communication Channels: Use dual network connections (e.g., Ethernet and cellular, or Wi-Fi and RS485) to provide redundancy in case of a network failure.

- Edge and Cloud Synchronization: Implement local buffering at the edge, allowing data to be stored temporarily during a network outage. Once the connection is restored, data can be synchronized with the cloud.

- Heartbeat and Monitoring: Regularly monitor the health of communication channels. If a failure occurs, a heartbeat mechanism can trigger an automatic switch to the backup communication channel.

- Data Replication: Store critical data at both the edge and cloud, enabling data redundancy in case of communication failure.

Example:

In a smart manufacturing facility, if the primary Ethernet connection to the cloud fails, the gateway can automatically switch to a cellular connection to maintain communication and prevent data loss, ensuring continuous operation.

Conclusion

The combination of edge computing with a Modbus to MQTT gateway and RS485 IoT gateway is revolutionizing industrial automation. By reducing latency, improving security, and optimizing bandwidth usage, businesses can achieve greater efficiency and real-time insights. As industries continue to embrace IIoT, leveraging edge computing will become essential for future-proofing operations.

FAQs

Q1: What is the primary function of a Modbus to MQTT gateway?

A Modbus to MQTT gateway translates Modbus data into MQTT messages for seamless IIoT integration.

Q2: Why is edge computing important for industrial IoT?

Edge computing enables real-time data processing, reducing cloud dependency and improving decision-making.

Q3: How does an RS485 IoT gateway enhance Modbus communication?

An RS485 IoT gateway extends Modbus RTU capabilities, allowing connectivity with modern IP-based networks.

Q4: What security measures should be implemented for Modbus to MQTT gateways?

TLS encryption, user authentication, and access controls should be enforced for secure communication.

Q5: Can edge computing replace cloud computing in industrial IoT?

No, edge computing complements cloud computing by handling time-sensitive operations locally while the cloud manages long-term analytics.