According to the International Energy Agency (IEA), heating, ventilation, and air conditioning (HVAC) systems account for nearly 40% of total energy use in buildings. Additionally, inefficient cooling systems can reduce equipment lifespan by up to 30%. Temperature control plays a key role in modern homes, industries, and data centers. A precise and automatic system for controlling fan speed can help in saving energy and improving equipment life. IoT-based fan speed control systems offer a way to do this using real-time temperature data. As industries move toward automation, an IoT Development Company can design smart solutions that improve efficiency and reduce manual work.

Table of Contents

- Importance of Temperature Control in Modern Systems

- Role of IoT in Automation

- Why Temperature-Based Fan Speed Control Matters

- Components of an IoT Temperature-Based Fan Control System

- Circuit Diagram & Connection

- Project PCB Gerber File & PCB Ordering Online

- How the System Works

- Blynk 2.0 Web & Mobile Dashboard Setup

- Testing: IoT Temperature-Based Fan Speed Control System

- Key Benefits of the System

- Real-World Applications

- Role of an IoT Development Company

- Example Case Study

- Challenges and Solutions in IoT-Based Fan Speed Control

- Future Trends in IoT Fan Control Systems

- Build Smart IoT Solutions with HashStudioz IoT Development Company

- Conclusion

- Frequently Asked Questions (FAQ)

Importance of Temperature Control in Modern Systems

In today’s energy-conscious world, managing temperature effectively is crucial. Temperature control systems, such as fans and HVAC units, are integral to maintaining optimal conditions in various environments, including homes, offices, and industrial settings. However, traditional systems often operate at fixed speeds, leading to energy inefficiency. Implementing dynamic temperature-based control can significantly reduce energy consumption and enhance comfort.

Role of IoT in Automation

The Internet of Things (IoT) has revolutionized automation by enabling devices to communicate and make intelligent decisions. Incorporating IoT into temperature control systems allows for real-time monitoring, remote access, and adaptive responses to environmental changes, leading to smarter and more efficient operations.

Why Temperature-Based Fan Speed Control Matters

Energy Consumption in Cooling Systems

Cooling systems, especially fans, often operate at full capacity regardless of the actual temperature, leading to unnecessary energy consumption. By adjusting fan speeds based on real-time temperature data, energy usage can be optimized, contributing to lower electricity bills and reduced environmental impact.

Benefits of Automated Cooling

Automated cooling systems respond promptly to temperature fluctuations, ensuring comfort without manual intervention. This automation not only enhances user convenience but also prolongs the lifespan of cooling equipment by preventing overuse and wear.

Components of an IoT Temperature-Based Fan Control System

Hardware Components

1. Temperature Sensors

Devices like the DHT11 or DHT22 sensors measure ambient temperature and humidity levels. These sensors provide the necessary data to adjust fan speeds accordingly.

2. Microcontroller

A microcontroller, such as the ESP8266 or ESP32, processes the sensor data and controls the fan’s operation. It serves as the central unit that executes the control logic.

3. Relay or Motor Driver Module

A relay or motor driver module acts as a switch, allowing the microcontroller to control the fan’s power based on the processed data.

4. Wi-Fi Module

Integrated into microcontrollers like the ESP8266, the Wi-Fi module enables remote monitoring and control of the fan system via the internet.

5. Cooling Fan

The fan adjusts its speed based on commands from the microcontroller, providing cooling as needed.

Software Components

1. IoT Platform

Platforms like Blynk or ThingSpeak facilitate data visualization and remote control through user-friendly dashboards.

2. Mobile/Web Application

These applications allow users to monitor and control the fan system remotely, providing real-time insights and adjustments.

3. Firmware Programming

Custom firmware is developed to implement the control logic, sensor data processing, and communication with the IoT platform.

Circuit Diagram & Connection

The schematic below shows the IoT Temperature-Based Fan Speed Control & Monitoring System using ESP8266. The connections are straightforward and easy to follow.

The circuit is powered by a 12V DC supply, which is mainly required for the DC fan. Other components operate on 5V, provided through a 7805 voltage regulator IC. The DS18B20 waterproof temperature sensor connects to pin D6 of the NodeMCU ESP8266. Its VCC and GND are linked to 3.3V and GND on the NodeMCU. A 4.7KΩ pull-up resistor is connected to the sensor’s data line.

To display temperature and fan speed, a 16×2 I2C LCD display is used. Connect its VCC, GND, SDA, and SCL to 5V, GND, D2, and D1 of the NodeMCU, respectively.

Since the digital pins of the NodeMCU cannot drive a 12V fan directly, an IRF540 MOSFET is used. Pin D0 of the NodeMCU connects to the Gate terminal of the MOSFET. The IRF540 acts as a switch, allowing the control of the higher voltage fan with a small voltage signal from the NodeMCU.

I assembled all the components on a zero PCB. For the power supply, you can use either a 12V DC adapter or a 12V battery. In my case, I am powering the circuit with an 11.2V Lithium-Ion battery pack.

Project PCB Gerber File & PCB Ordering Online

If you prefer not to assemble the circuit on a zero PCB and want a dedicated PCB for your project, here’s an option for you. I used EasyEDA to design the schematic first and then converted it into a PCB layout. The PCB board for this project appears similar to the one shown below.

To order the PCB, simply upload the Gerber File by selecting the Quote Now option. You can then choose the Material Type, Dimensions, Quantity, Thickness, Solder Mask Color, and other necessary parameters.

Once you’ve filled in all the details, select your country and shipping method, and then place your order.

After receiving the PCB board, you can easily assemble the components onto it.

You can assemble the components on the PCB Board.

How the System Works

1. Data Collection and Processing

The temperature sensor continuously monitors the ambient temperature and sends the data to the microcontroller. The microcontroller processes this data to determine the appropriate fan speed.

2. Fan Speed Control Mechanism

Based on the processed data, the microcontroller adjusts the fan’s speed by controlling the relay or motor driver module, ensuring optimal cooling.

3. Data Upload and Remote Access

The microcontroller uploads the sensor data to the IoT platform via the Wi-Fi module, allowing users to monitor and control the system remotely through a mobile or web application.

Blynk 2.0 Web & Mobile Dashboard Setup

Blynk 2.0 provides an intuitive interface for creating dashboards to monitor and control IoT devices. Users can add widgets like gauges and buttons to display temperature readings and control fan settings remotely. Detailed setup guides are available on platforms like .

Go to blynk.io and create an account using your email address.

Once logged in, click on Create New Template.

Assign the name, Hardware & Connection Type.

From the Web Dashboard, create 4 widgets: Gauge, Label, LED & Slider.

For the Gauge setting, choose the Virtual pin V4. This will be used for displaying the fan speed in percentage.

For temperature display in a label, select virtual pin V3 and data type as integer.

For the slider, assign the virtual pin as V7. The slider is used to set up the threshold value at which the fan would turn on.

For the LED setting, rename the variable as Fan as this will indicate the fan ON/OFF status. The virtual pin assigned for the fan is V0.

In addition to the Web Dashboard, you can also configure the Mobile App Dashboard. To do this, download the Blynk app from the Play Store or App Store. The mobile dashboard will provide the same functionality and observations as the web dashboard.

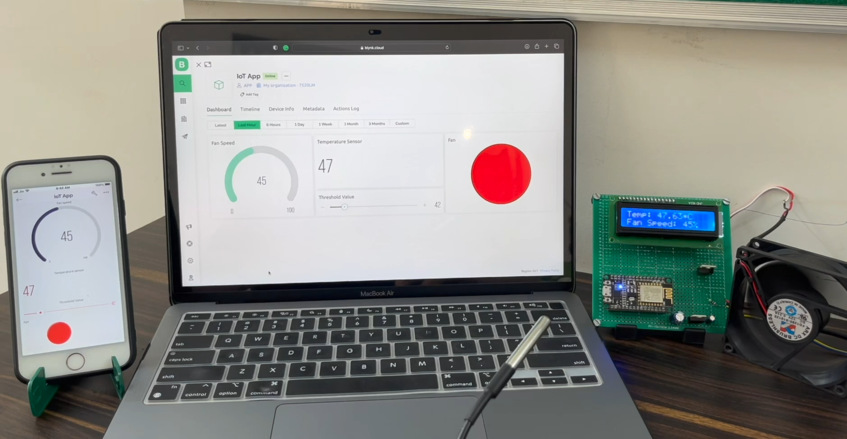

Testing: IoT Temperature-Based Fan Speed Control System

Once you upload the code, the ESP8266 connects to your WiFi network. After a successful connection, it links to the Blynk platform using the Blynk authentication token.

At the same time, the 16×2 LCD display shows the current temperature in degrees Celsius and the fan speed as a percentage.

On the Blynk app, you will also see the temperature (°C) and fan speed through the gauge widget. The app will show the fan’s ON/OFF status and display the threshold value set with the slider.

By default, the temperature threshold is set to 30°C. If the temperature rises above this value, the fan turns on automatically. The fan speed increases gradually from 0% to 100% as the temperature rises between the threshold (30°C) and the upper limit (55°C). If the temperature stays below the threshold, the fan remains off.

You can adjust the threshold value using the slider on the Blynk app.

When the sensor detects higher temperatures, the fan activates, and its speed is directly proportional to the temperature. At 55°C, the fan runs at full speed (100%). You can change the upper temperature limit in the code as needed.

The greater the temperature the greater the Fan speed. At a temperature of 55°C, the fan speed becomes 100%. You can change the value of the upper limit of temperature in the code part.

The same information is available on the Blynk web dashboard. You can monitor both fan speed and temperature from anywhere in the world.

This is how you can build and set up the IoT Temperature-Based Fan Speed Control and Monitoring System using the ESP8266 and the Blynk application.

Key Benefits of the System

1. Improved Energy Efficiency

One of the most significant advantages of this system is its ability to enhance energy efficiency. The system continuously monitors temperature data in real time and adjusts fan speeds accordingly. By operating the fan only when necessary and at optimal speeds it minimizes unnecessary energy consumption. This dynamic adjustment significantly reduces power usage, resulting in lower electricity bills. In both residential and industrial environments, this improved efficiency can lead to substantial long-term savings.

2. Cost Reduction

Efficient energy management directly impacts cost savings. By optimizing the fan’s operation to match real-time temperature changes, the system prevents excessive power use. This not only cuts down on energy bills but also reduces maintenance and repair costs due to less wear and tear on the equipment. Whether in a household or a large industrial facility, the system’s ability to minimize energy waste can lead to considerable financial benefits.

3. Enhanced Equipment Life

By ensuring that the fan operates within optimal parameters and preventing overuse, the system significantly extends the lifespan of cooling equipment. Continuous, unnecessary operation can cause overheating and mechanical stress, leading to premature failures. With this system in place, fans run efficiently and only when needed, which reduces mechanical strain and enhances durability. As a result, maintenance frequency decreases, and equipment remains reliable over a longer period.

4. Remote Monitoring Capabilities

A key feature of this system is the ability to monitor and control it remotely. Users can access the system via a web or mobile dashboard, allowing them to adjust settings and check the fan status from anywhere. This remote functionality provides convenience and ensures quick responses to changes in environmental conditions. Whether managing a cooling system in a remote industrial plant or maintaining home ventilation, users benefit from real-time insights and control without needing to be physically present.

Real-World Applications

1. Data Centers

Efficient cooling is critical in data centers to prevent equipment overheating. IoT-based fan control systems can dynamically adjust cooling based on temperature readings, enhancing energy efficiency.

2. Industrial Manufacturing

In manufacturing environments, maintaining optimal temperatures is essential for ensuring the efficiency and longevity of machinery, as well as maintaining product quality. Excess heat can lead to equipment malfunctions, reduced performance, and increased downtime. An IoT temperature-based fan control system automatically adjusts cooling based on real-time conditions, preventing overheating, improving safety, and reducing energy costs. By using data-driven automation, manufacturers can optimize their operations and reduce manual intervention.

2. Industrial Manufacturing (continued)

In manufacturing environments, maintaining optimal temperatures is essential for both machinery and product quality. An IoT temperature-based fan control system ensures that cooling is delivered precisely where and when needed, preventing overheating of equipment and improving safety.

3. Smart Homes

Smart homes benefit significantly from automated temperature control. By integrating this system, homeowners can enjoy a comfortable indoor environment while reducing electricity consumption. It also adds to the overall smart home ecosystem, enhancing convenience and energy management.

4. Greenhouses

Greenhouses require precise temperature control to support plant growth. With IoT-enabled fan systems, greenhouse temperatures can be regulated automatically based on sensor data, ensuring ideal growing conditions and conserving energy at the same time.

Optimizing Wind Turbine Performance with IoT Gateway-Based Monitoring Systems

Role of an IoT Development Company

1. Hardware and Software Integration

An IoT Development Company plays a critical role in successfully implementing such systems. They are responsible for designing and integrating both the hardware (sensors, microcontrollers, connectivity modules) and software (control algorithms, cloud platforms, user interfaces), ensuring seamless communication and performance.

2. Customization for Industry Needs

Each industry may have specific requirements. An experienced IoT development company can customize the temperature-based fan control system to suit various applications—whether in a small server room or a large industrial plant—by selecting the right components and tuning the control logic.

3. System Security and Reliability

Security and reliability are crucial in IoT deployments. IoT development companies implement robust encryption, authentication mechanisms, and fail-safe features to protect data and maintain operational continuity even in adverse conditions.

Example Case Study

Company X: Electronics Factory in India

An electronics manufacturing company in India partnered with an IoT development company to implement an automated fan speed control system across their production floors. The aim was to reduce energy costs and prevent overheating of sensitive equipment.

Key Outcomes and Benefits

- Energy Efficiency: The system reduced the factory’s overall cooling energy consumption by 30%.

- Cost Savings: Significant reduction in monthly electricity bills.

- Equipment Longevity: Machines operated within optimal temperature ranges, reducing wear and failure rates.

- Real-Time Monitoring: Management could view temperature and fan operation in real-time through a centralized dashboard.

Challenges and Solutions in IoT-Based Fan Speed Control

Implementing IoT-based fan control systems comes with several challenges. Addressing these challenges effectively ensures smooth operation and reliable performance. Below are the key challenges and their practical solutions:

1. Sensor Accuracy

Challenge:

One of the primary challenges in IoT-based fan control systems is sensor accuracy. Inaccurate or delayed temperature readings can result in inefficient fan control, leading to energy wastage or inadequate cooling. This issue can arise from low-quality sensors, environmental interference, or signal degradation.

Solution:

To ensure precise temperature monitoring, it is crucial to use high-quality, calibrated sensors. These sensors should be capable of delivering consistent and accurate data over long periods. Additionally, implementing data filtering algorithms can help eliminate anomalies and smooth out sudden fluctuations. Techniques like Kalman filtering and moving average algorithms can process raw data to provide stable and reliable readings, ensuring that the system makes data-driven decisions effectively.

2. Network Stability

Challenge:

IoT systems rely heavily on stable internet connectivity to transmit data and receive commands. However, temporary network outages or unstable connections can disrupt the system’s functionality, particularly in remote or industrial settings. This dependency on continuous connectivity can limit the system’s reliability.

Solution:

Incorporating edge computing can address this challenge effectively. Edge devices can process and analyze data locally, allowing the system to make decisions without relying solely on cloud servers. This means that even during network disruptions, the fan control system can continue to operate using locally stored data and predefined algorithms. Additionally, maintaining a backup communication method, such as a local Wi-Fi network, can ensure uninterrupted performance.

3. Data Security

Challenge:

IoT devices are potential targets for cyberattacks, as they often collect sensitive data and are interconnected with other systems. Hackers can exploit vulnerabilities to gain control of the system or manipulate data, posing risks to both security and functionality.

Solution:

Implementing robust security measures is essential to safeguard IoT-based fan control systems. Use secure communication protocols like HTTPS and MQTT with TLS (Transport Layer Security) to encrypt data transmission. Additionally, enforce strong user authentication methods, including multi-factor authentication (MFA), to restrict unauthorized access. Regularly updating firmware and applying security patches can help address known vulnerabilities and protect the system against emerging threats.

4. System Scalability

Challenge:

Expanding the system to cover larger areas or additional devices can be complex and resource-intensive. Integrating new sensors and fan units while maintaining seamless operation can become challenging, especially in industrial setups.

Solution:

To address scalability, design the system using a modular architecture. This allows for easy integration of new components without disrupting the existing setup. Utilizing cloud-based platforms with scalability features makes it easier to add devices, create zones, and manage data from multiple locations. Cloud platforms like AWS IoT or Microsoft Azure IoT Hub provide built-in tools for scaling up operations efficiently.

Future Trends in IoT Fan Control Systems

As technology advances, IoT fan control systems are evolving to become more intelligent, efficient, and user-friendly. Here are some key trends shaping the future of these systems:

1. Edge Computing

Edge computing enables data processing closer to the data source rather than relying solely on cloud servers. This reduces latency, allowing the system to respond faster to real-time temperature changes. It also minimizes the dependency on continuous internet connectivity, making the system more resilient in environments where network stability is an issue. Edge devices can make autonomous decisions, which is crucial for critical applications such as industrial cooling.

2. Artificial Intelligence Integration

Integrating Artificial Intelligence (AI) into IoT fan control systems takes automation to the next level. AI algorithms can analyze historical temperature data and predict future trends, allowing proactive adjustments to fan speed. For instance, machine learning models can learn typical temperature patterns and adjust the fan settings accordingly, optimizing cooling performance while reducing energy consumption. AI-driven insights also help identify inefficiencies, enabling predictive maintenance and minimizing downtime.

3. Energy Analytics and Reporting

Future systems will emphasize detailed energy analytics and reporting. These systems will not only monitor real-time energy usage but also generate comprehensive reports that highlight patterns, inefficiencies, and areas for improvement. By analyzing data, users can gain actionable insights into how the fan system performs over time. Implementing analytics dashboards will help in visualizing energy trends, making it easier to make data-driven decisions for further optimization.

For instance, businesses can use these reports to identify peak energy usage periods and adjust fan operation schedules accordingly. This helps in maintaining a balance between comfort and energy efficiency, ultimately reducing operational costs.

Build Smart IoT Solutions with HashStudioz IoT Development Company

Want to deliver efficient, automated, and intelligent temperature control systems for your users? IoT-based fan speed control solutions combine real-time data with automation, giving your business an edge in smart environment management. HashStudioz offers expert IoT Development Services to help you create reliable, user-friendly solutions for homes, industries, and enterprises.

Our IoT Development Services at HashStudioz include sensor integration, cloud dashboard development, real-time monitoring apps, and hardware-software interfacing—powered by experienced engineers and industry-tested platforms.

Let HashStudioz help you launch scalable IoT-based systems that improve efficiency, save energy, and open new automation opportunities without the limits of manual controls.

Conclusion

An IoT Temperature-Based Fan Speed Control and Monitoring System is a powerful tool for improving energy efficiency, equipment longevity, and operational convenience in various settings—from homes to industrial facilities. With the help of an experienced IoT development company, these systems can be tailored, secured, and scaled to meet specific needs. As technology continues to evolve, these solutions will become even smarter, more predictive, and integral to sustainable development goals.

Frequently Asked Questions (FAQ)

1. What is an IoT Temperature-Based Fan Speed Control System?

It is a smart system that adjusts fan speed automatically based on real-time temperature data using an IoT platform like Blynk and a microcontroller such as the ESP8266.

2. Which microcontroller is used in this project?

The ESP8266 NodeMCU is used because it has built-in WiFi, making it easy to connect to the Blynk platform and monitor data online.

3. What is the default temperature threshold for fan activation?

The default threshold is set at 30°C. The fan starts automatically when the temperature exceeds this value.

4. What is the upper temperature limit, and what happens at that point?

The upper limit is set at 55°C. At this temperature, the fan reaches its maximum speed of 100%.

5. How can I monitor the system remotely?

You can monitor temperature, fan speed, and fan status through both the Blynk mobile app and the Blynk web dashboard from anywhere in the world.